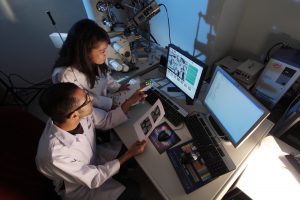

Professional Film Studios

IST has seven high-definition film studios for the purpose of capturing video-based teaching using some of the best equipment available in the cinematic industry. Teachers create innovative and engaging lessons using resources such as a green screen studio and animation inserts.

Our focus is the Art of Teaching Online as teachers view themselves and analyze student learning data resulting from their lessons. We challenge teachers to think outside the box to create captivating Acellus lessons that engage K-12 students.

Industrial Electron Beam Melting 3D Printer

IST’s prototyping facilities include a $1.6M GE Arcam Electron Beam Melting 3D Printer. Electron beam melting is a 3D printing technology developed in Sweden that uses an electron beam to fuse metal powder together to build parts. This 3D printer can withstand temperatures as high as 1,000° Celcius so as to work with materials like titanium aluminide (TiAl) and nickel alloy. The machine can handle the heat while handling a few of the toughest alloys that could not be used with any other 3D printing process.

The 3D printer is capable of high precision printing with production-grade metal alloys. For example, Boeing’s new 777x aircraft features two GE9x engines, each of which has over 300 3D printed parts, including several dozen blades that are all 3D printed in titanium alumide using the GE Arcam 3D printer.

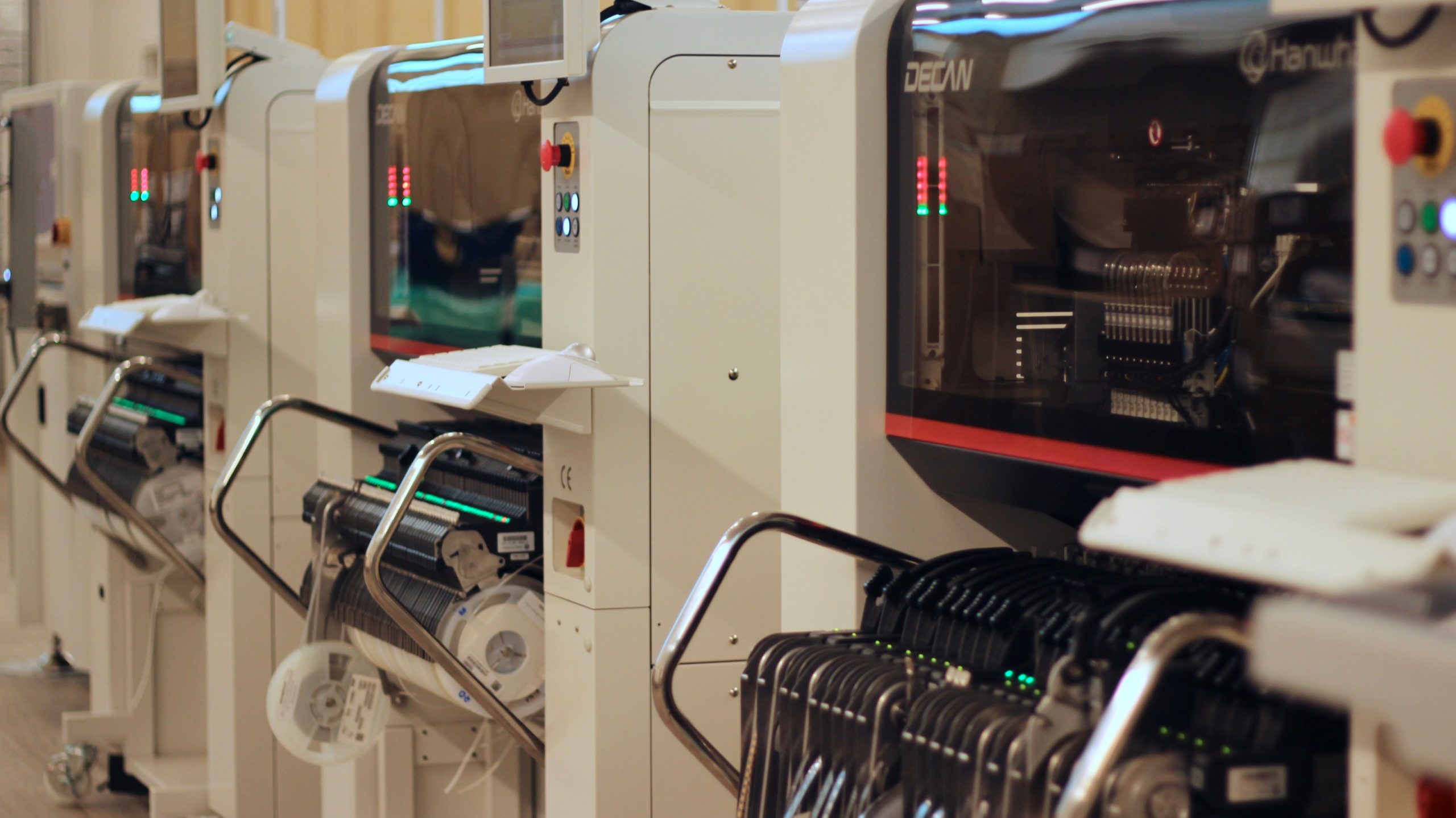

Hanwha Robotic Pick-and-Place Assembly Line

A pick-and-place (PNP) machine is a robotic assembly device that uses a vacuum to lift a component off of a piece of tape, rotate it to the right orientation, then place it on a circuit board.

They are used for high speed, high precision placing of broad range of electronic components, like capacitors, resistors, integrated circuits onto a printed circuit board (PCB) which are in turn used in computers, consumer electronics as well as industrial equipment. This automated assembly line allows IST to design custom electronics equipment and produce the design cost-effectively.